|

CMOS Compatible Optical

Leaky Wave Antennas (OLWAs) and Devices Sponsored by NSF – ECCS |

|

MOTIVATION Ř What are Leaky Wave

Antennas? o Leaky wave antennas (LW

antennas) are travelling wave antennas that make use of the fast guided waves

to provide radiation. The LW radiates as it propagates through the waveguide o Fast-waves are also

named leaky waves, which mean the phase constant of the guided wave is

smaller than the free-space wave number. This type of waves ‘leak’ out of the

wave guide and can be utilized to design very directive antennas Ř Why “Optical”? o The optical frequency

range covers the electromagnetic spectrum extending from infrared (IR) to

ultraviolet (UV) o We are focusing on

radiation at 1550 nm, since it is the optical communication wavelength Ř Why SOI / CMOS

Compatibility? o It is basic chip

fabrication technology in use, accessible and cheap o It allows for reduced

parasitic capacitance and good mode confinement with low optical loss o It is compatible for

integration with CMOS electronics and can be tuned electronically to control far field

radiation |

|

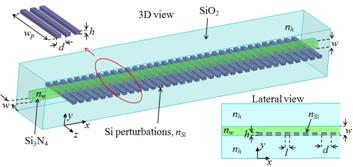

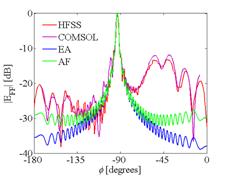

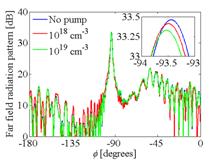

BASIC ANTENNA GEOMETRY AND RADIATION CAPABILITIES

Very directive radiation

is achieved. Beam width and beam angle are controlled by the LW phase

propagation and attenuation constants |

|||||||||

|

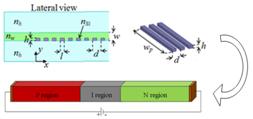

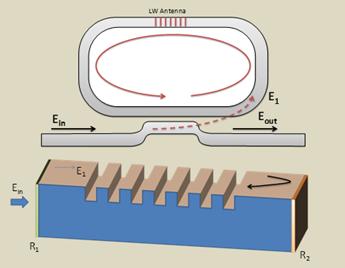

TWO DIFFERENT WAYS FOR

CONTROLLING THE RADIATION

Image taken from [4] This simple mechanism

currently does not provide great control of the radiated power at a single

direction. We are currently considering inserting the OLWA into resonators to

amplify the control |

|

ENHANCEMENT OF RADIATION

CONTROL BY INTEGRATING OLWA WITH A RESONATOR

Integrating OLWAs with

an optical resonator (ring or a linear cavity resonator) is one way of

achieving enhanced radiation control. In both cases, the variation of the

refractive index and losses will imply less coupling to the cavity and also a

weaker field in the cavity [5-7]. |

|

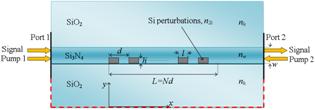

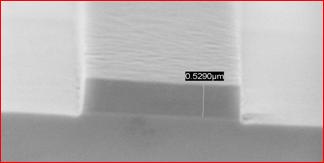

FABRICATION Fabrication of antennas

on silicon nitride on silicon: waveguides with strained dielectrics and

strained semiconductors has been fabricated. Currently nitride thickness is

being optimized for proposed antenna design.

Before we start

patterning with e-beam lithography, we developed the fabrication steps for strained

thick waveguide materials. In particular we use silicon on insulator, silicon

on sapphire and silicon nitride on silicon to control etch

profiles and waveguide smoothness for low loss operation. The difficulty of

the process arises due to strain level that leads to uneven etching and high

side wall roughness. Currently 4-step etching process has been adopted to

overcome this limitation. In the worst case scenario of highly strained

silicon on sapphire we achieve RMS surface roughness less than 25nm, Fig. 9.

In the following steps we optimize the growth of waveguide grade silicon

nitride on silicon to achieve 1μm thickness. |